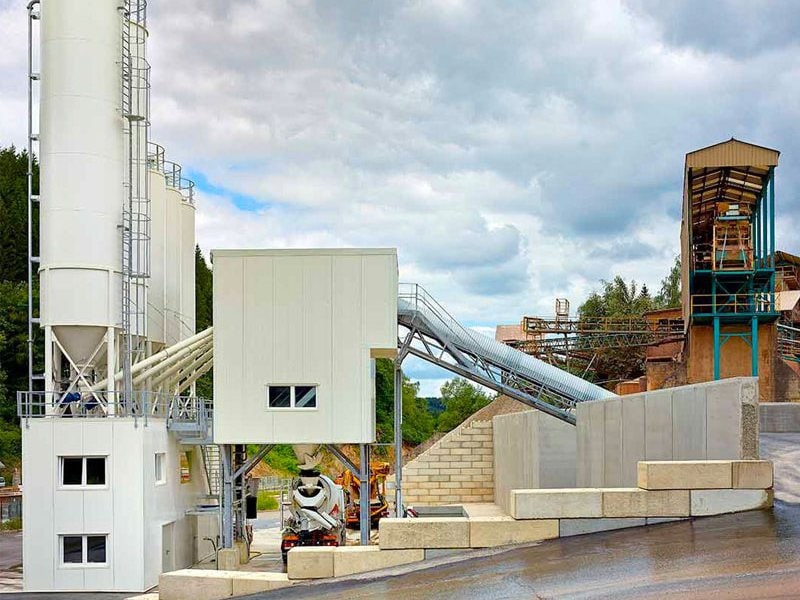

The Concrete Batch Plants Can Be Categorized Into 4 Parts

Concrete batching plants provide high mobility. Concrete batching plants can be installed in 1 hour without crane. Concrete batching plant provides the highest efficiency and low concrete quality at low capacity. No concrete foundation required. And also concrete batching plant provides production on site and direct application in small projects. The cost of concrete transportation can be saved and may be reduced.

The concrete batch plants can be categorized into 4 parts:

- Aggregate feeding,

- Powder feeding (fly ash, cement and expanding agent),

- Water and

- Admixture for mixing the materials, conveyance and storage.

There are two types of concrete batching plants:

Ready mix concrete batching plants: A ready mix concrete batching plant combines all ingredients except for water at the concrete plant. This mixture is then discharged into a ready mix truck. Water is then added to the mix in the truck and mixed during transport to the job site

Central mix concrete batching plants: A central mix concrete batching plant combines some or all of the above ingredients at a central location. The final product is then transported to the job site. Central mix plants differ from ready mix plants in that they offer the end user a much more consistent product, since all the ingredient mixing is done in a central location and is computer-assisted to ensure uniformity of product.

Concrete batching plant can produce in small concrete projects where less concrete is needed. It is installed in less than 1 hour and makes concrete possible where it is needed and when concrete is requiered. Concrete batching plants are designed to be shipped easily and with minimum cost. It is more profitable to purchase and sell for both consumers and sellers. Because of this profitability most of consumers and seller prefer concrete batching plants for their business.